Search products

-

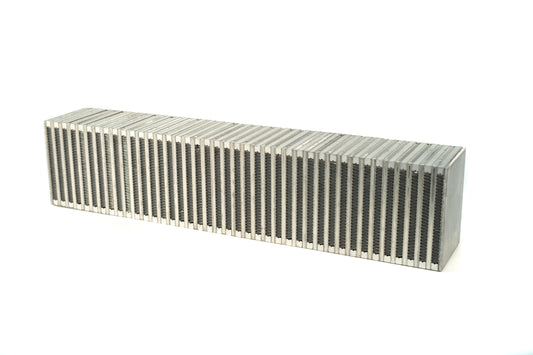

High-Performance Bar & Plate Intercooler Core 24x6x3.5 - Vertical Flow

Regular price £336.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 25x12x3.5

Regular price £480.00 GBPRegular priceUnit price per -

HP Bar & Plate Intercooler Core 22Lx14Hx4.5W - Vertical Flow / R35 GT-R Fitment

Regular price £696.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 27x6x4.5 - Vertical Flow

Regular price £480.00 GBPRegular priceUnit price per -

The MAGNUM 1000HP+ Intercooler Core 18X12x6 Bar & Plate design

Regular price £576.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 27x6x6 - Vertical Flow

Regular price £528.00 GBPRegular priceUnit price per -

HP Bar & Plate Intercooler Core 22Lx14Hx5.5W - Vertical Flow / R35 GT-R Fitment

Regular price £744.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 22x12x4.5

Regular price £516.00 GBPRegular priceUnit price per -

High-Performance Bar & plate Intercooler Core 22x10x4

Regular price £420.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 27x6x3 - Vertical Flow

Regular price £408.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 25x12x4.5

Regular price £540.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 24x12x3

Regular price £396.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 22x12x3.5

Regular price £444.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 20x12x4

Regular price £432.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 20x12x3

Regular price £360.00 GBPRegular priceUnit price per -

High-Performance Bar & Plate Intercooler Core 18X12x4.5

Regular price £420.00 GBPRegular priceUnit price per

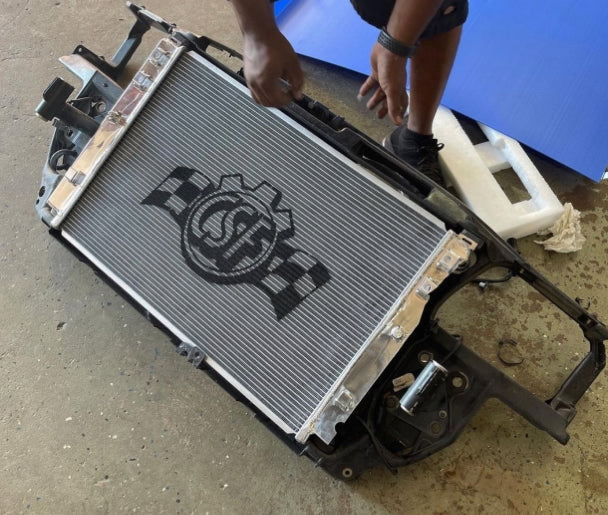

Build quality and performance is great

“Used these radiators to keep my track Porsche cool and also my supercharged E39 in check. Build quality and performance is great, so much so that I've got the engine oil cooler, DCT cooler, power steering cooler and radiator for my E92 M3.”

Ryan Stewart